The Goals

BekaertDeslee aims to own the first-choice digital selection platform for bed designs and mattress covers for their customers. Therefore, the company started a co-creation project with Schacht One that is highly focused on the core business to sharpen the design leadership and to help the customers of BekaertDeslee in bringing new mattresses to the market with success. In the short term, BekaertDeslee has defined a roadmap for the BD Cloud – a virtual showroom – where generating content and driving user adoption are the two main priorities.

Smart Sleeping

E-business of sleep enhancing fabrics and covers will bring BekaertDeslee close to the consumer, for example with the SmartSleeve collection. SmartSleeve products support sleeping comfort by, for example, regulating moisture or preventing bad bacterial growth. BekaertDeslee is already present on e-tail platforms and websites such as Amazon, Emma, Casper, etc. to make it possible for consumers to buy these intelligent textiles. The long shot will be to build an e-business platform of sleep enhancers by creating a pull effect from the consumers. The business in the USA will be managed by a B2C marketing specialist and digital native located in the USA, who has started in February 2018. After an 8 to 10-month period of learning, research and business model validation, the SmartSleeve brand will be launched into the market.

New ways of learning

BekaertDeslee is going to integrate a brand-new e-learning management system that will make it possible to train and coach the organisation on a wide range of different topics, such as product information, work processes, new digital tools, etc. This system will first be launched for employees working in commercial areas as a pilot project by the end of June 2018. The analytics provided within the system will allow all trainers to adapt and refine the training offer.

The Goals

CWS-boco’s goal is to be an international market leader in the field of innovative and digital rental service solutions. To that end, the specialist for workwear and washroom hygiene is focusing on digitalisation in all areas. For example, digital service and product innovations such as equipping rented textiles with RFID chips and smart washroom solutions are being driven forward. Another emphasis is on digital communication that allows fast, dynamic dialogue with customers.

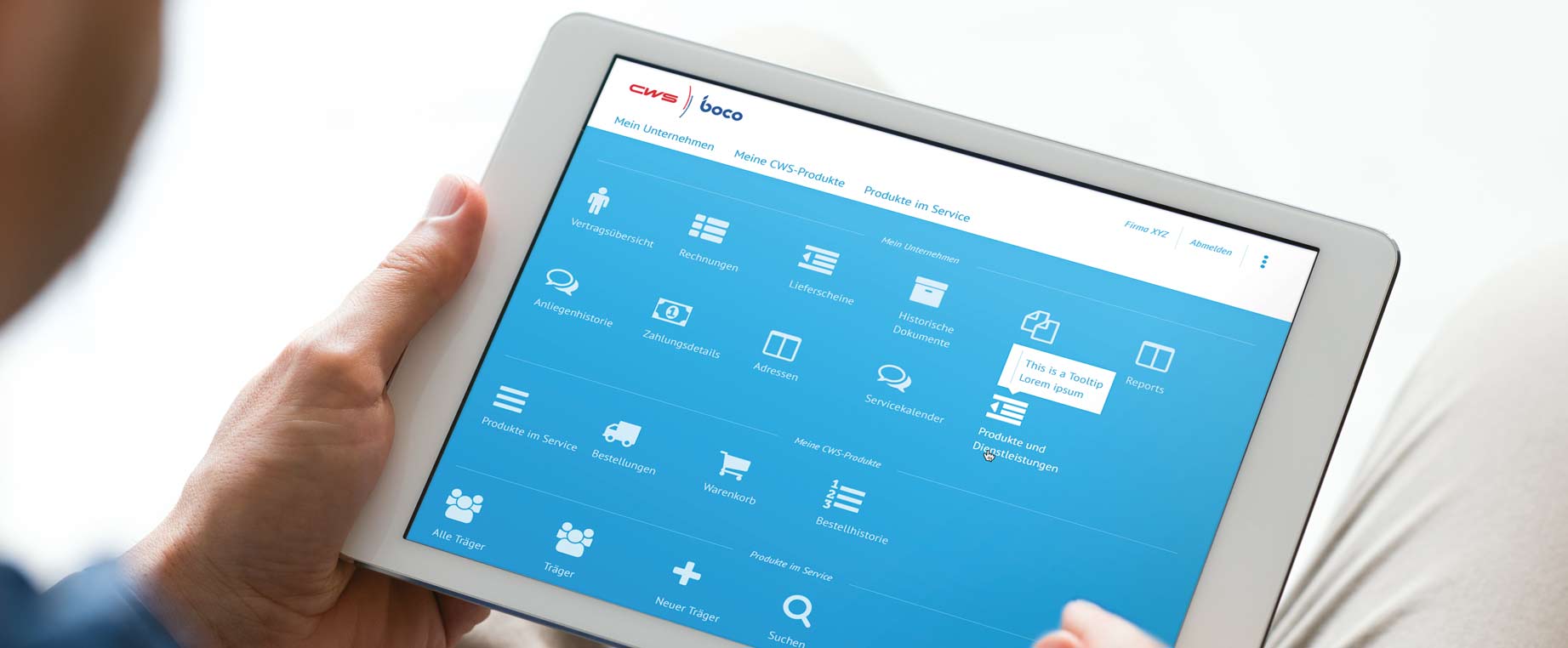

Digital platform for customers

Modify agreements digitally, view invoices and delivery notes online: These and other services are offered by the new “My CWS-

boco” customer portal, which has been online since October 2017 in Germany and previously went live in Poland, the Netherlands, Belgium and Switzerland. Soon after the launch, more than 10,000 customers are already using these time-saving services. The portal is being continually enhanced and will gradually also be available in additional countries.

Social Selling

In 2017 CWS-boco further expanded its social media presence and continually oriented the content on the target groups. This will increasingly lead users to the website with the right suitable product and service information and the new corporate blog. In addition, CWS-boco is expanding social selling further by training sales employees in the use of social media. Using the blog, they can share current relevant background information and content requiring explanation with customers and thus demonstrate their expertise. The goal: Expand their own network and have one-to-one dialogues with potential customers.

Digital fellows

The www.fello.online platform was developed especially for smaller companies such as craft-based businesses. Since fall 2017, customers can rapidly and easily rent workflows through this platform. fello offers a reduced product selection and lean services in the monthly subscription. CWS-boco is using this pilot project to test the demand for fast services for work clothes on a digital level.

The Goals

The key to the success of the digital transformation at ELG is building on the existing internal know-how and allowing and further developing completely new ways of thinking in the same measure – always with a focus on the requirements of customers and suppliers. In order to reach that goal, ELG founded the “ELG Innovation Experience” initiative in 2016, which was renamed EIE Service GmbH in April 2017, and which bundles and manages all innovation and digital projects and initiatives. This unit will initiate both innovative process improvements in the core business and support existing as well as develop completely new business models in the secondary raw materials segment.

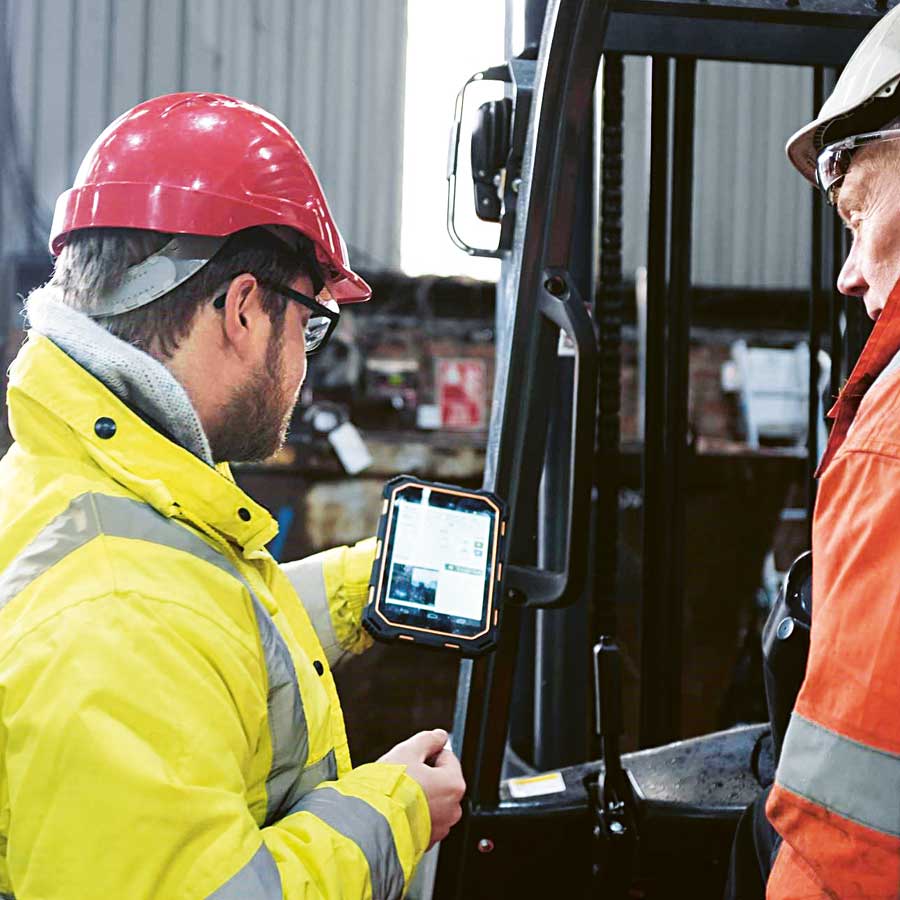

An eye on scrap

Hundreds of tons of raw materials are accepted, weighed, tested, moved and valued at 50 ELG scrap locations globally. SmartYard, developed as a pilot project in Sheffield, records every step in a track & trace system. This makes the process in each of the materials preparation stage transparent so that the customer can receive information about weight, analysis results, and the expected selling price as quickly as possible. Thanks to its modular structure, SmartYard presents a cost-effective solution and makes a broad range of applications in raw materials recycling possible.

Digital urban mining

With remetal.de, ELG offers an online portal through which owners of scrap find fair and adept customers for their waste metals scrap at any time – regardless of quantity, quality and location. remetal thus creates transparency in the supply chain, and at the same time, saves raw materials out of the scrap bin. Experience founders, digital natives and recycling experts work together as a team on the right solutions for all participants in the remetal platform. In addition, ELG offers deinschrottplatz.de, a search portal for nearby scrapyards:

The Goals

Optimar is currently working to develop its own digital platform which makes it possible for production data to be collected and analysed at any time. For customers, this means control and insight into operating processes so that they are better equipped to take decisions, optimise their production processes and increase value by adding quality and profit. By continuing to digitalise its business, Optimar – which has been part of the portfolio only since the end of 2017 – can rely on Haniel’s expertise. The basis for doing so is formed by a Digital Agenda, which Optimar sets in cooperation with Haniel.

The Goals

ROVEMA is meeting the needs of digitalisation with consistent control and data recording. For more than 20 years already, internally-developed software has ensured that even complex automated packaging equipment and systems function. In future, real-time simulations will be run at the very beginning of projects to provide information about complex packaging processes – without using any materials. ROVEMA also plans to expand the integrated assistant systems and simplify connecting customer systems. ROVEMA is thus able to satisfy the requirements of Industry 4.0.

Innovations with a future

At the important Interpack tradeshow in 2017, ROVEMA again presented itself as an innovative industry leader – including for digital solutions. For example, the company presented machines that already meet the requirements of the Internet of Things in that they can be easily networked and provide production data at all times. ROVEMA customers can use this data to optimise machine performance and reduce downtimes. One innovation that ROVEMA presented at Interpack is a “learning” final packaging machine: It continually adjusts its movements to the speed of the product feed.

Human and machine in dialogue

ROVEMA presented the new Human Machine Interface (HMI) in 2017. This user interface is characterised by intuitive and easily understandable operation. Among other things, it allows remote access to the machine and presents compacted information so that important process parameters are available immediately in an understandable form. The first machines equipped with the new HMI were delivered to Germany and the US in October. ROVEMA received the Red Dot Award for the HMI, one of Europe’s most important design awards.

The Goals

TAKKT intends to double its e-commerce business by 2020. By prioritising the digitalisation of its business model and focusing its actions on the constantly changing needs of its customers, the B2B direct marketing specialist is changing the organisation for the long term. In addition, up to EUR 50 million will be invested in employees and new technologies by 2020. TAKKT wants to increase organic growth over the medium term through these measures.

New port

In January 2018, TAKKT formed an additional segment within the TAKKT EUROPE division for establishing new business models: The newport Group will bundle the online business activities with TAKKT’s venture capital activities under one roof. The group gives these younger, fast-growing business models a home port in which they can position themselves in the market more strongly and independently than previously with their brand management, product lines and technology infrastructure. That makes them better able to focus their business model on the needs of smaller corporate customers.

Founder on the starting line

TAKKT investment company, once at the beginning of 2016, is also part of the newport Group. As a “smart investor”, the company supports young enterprises with knowledge and its international network. In exchange TAKKT receives access to know-how from start-ups with respect to markets and innovations and can participate in the enterprises’ robust growth. At the end of 2017 there were seven investments in the investment portfolio. This includes parcelLab, a Munich-based start-up that offers a technological solution for intelligent shipment monitoring and automated customer communications. The eighth and most recent investment was made by TAKKT in early 2018, in the Cologne-based company odoscope – a platform specialising in real-time analyses of large quantities of data.

Modern work environments

Now that the US-based companies NBF, Hubert and Displays2go have rebuilt and modernised their premises, TAKKT is completely redesigning its headquarters in Stuttgart: There will be work environments with modern infrastructure that promote cross-divisional collaboration and communication – including mobile jobs, creative spaces and quiet zones. The first rooms were ready for occupancy already at the end of the year.